Water/Wastewater

NETZSCH Team is present at the Energy Decentral 2016

Oct 27 2016

NETZSCH exhibits at the Energy Decentral 2016 in Hannover, its products for the biogas production. To ensure smooth conveyance in these applications NETZSCH combines different types of pumps that are especially adapted to the demanding operating conditions. The specific design of the pumps is selected for the corresponding medium and pressure required and also with a view to the existing installation space. Thus, in conjunction with the coarse material macerators, high operating safety and reliability is attained.

NETZSCH exhibits in Hall 25, booth G17

Due to the risk of blockage M-Ovas® cutting plate grinders are installed upstream of NETZSCH pumps or other process equipment, that finely cut up any coarse material so that the conveying sequence is not impaired. An integrated separator collects foreign matter, such as stones, that can then easily be removed through a separate cleaning aperture. Fibrous solid materials are ground in a cutting unit using hard metal blades. A flywheel assists the drive, thus reducing the energy required. The complete system, including the drive inclined upwards, is of a very compact design, so that it only requires a little space.

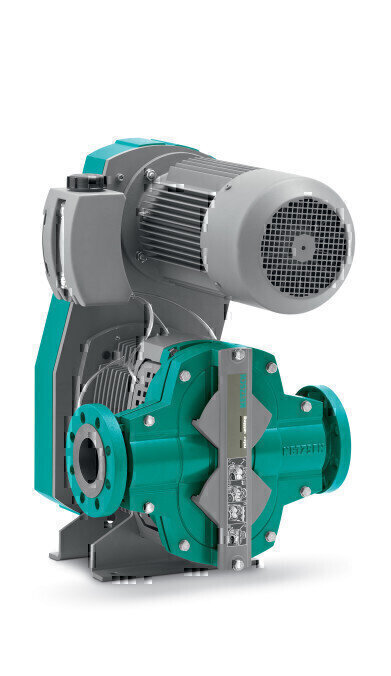

Space-saving rotary lobe pumps for transporting waste water

For this reason, the rotary lobe pumps type TORNADO® are often selected, too. Their footprint is small, because the motor has been placed above the pump chamber. The pump features a high power density and depending on the design, up to 1000 m³/h at up to 8 bar can be conveyed.

In addition, the spatial separation of pump and gearbox protects the TORNADO® pump against damage and operation shutdowns due to leakage of the medium. Maintenance and cleaning tasks are carried out with ease: The large front cover can be easily removed, so free access to all wetted parts is given. The straight rotary lobes can be installed and removed very easily and separately from one another. The pumps are very robustly designed and, due to their large free ball passage, correspondingly large foreign matters or content material can be conveyed with no problem.

Pressure-stable conveyance of thick sludge using progressing cavity pumps

Thickened sludge contains approximately eight to eleven percent of dry matter content and, due to its composition, no longer features linear flow characteristics similar to water. In order to ensure consistent conveying, NEMO® progressing cavity pumps are installed.

Thereby, pressure and conveying volume remain stable, independent of the consistency or viscosity of the medium. Also, very few shear forces or pulsation occurs that could influence the medium and make conveying difficult. Whilst filling the chambers with the high viscosity medium, the bevelled stator inlet also assists. As required, the coupling rod can also be equipped with a feeding screw. In this manner, a throughput of up to 400 m³/h at up to 48 bar can be realised.

NEMO® progressing cavity pumps are now available in Full-Service-in-Place® design. It enables a particularly service-friendly maintenance without dis-assembling of the pump from the pipeline. The downtimes and the associated costs are reduced. In addition, the new design shortens the required installation space, since the stator is removed laterally.

Events

Elmia Water and Wastewater Fair - POSTPONED

Sep 24 2024 Jonkoping, Sweden

Oct 01 2024 Ljubljana, Slovenia

Oct 01 2024 Dubai, UAE

Oct 05 2024 New Orleans, LA., USA

Oct 09 2024 Birmingham, UK

..jpg)