Water/Wastewater

Innovative foam & filament removal system

Mar 12 2009

Foaming problems on activated sludge plants are well known. A common cause in domestic wastewater treatment is the presence of excessive foam-causing filaments such as Microthrix parvicella and “nocardioforms”. These filaments are relatively easy to recognise, but their cause is often more elusive. Very often they are associated with high FOGs (fats, oils and greases), in the influent stream, a lack of inadequate primary treatment, septicity and / or biological nutrient removal (BNR) processes.

Once foam-causing filaments become established, they can be difficult to eradicate. The foam that they create is stable and provides an ideal environment and a readily available foodsource, including FOGs, dead cell material and septic conditions. In addition, the foam continually reseeds the plant, giving these filaments a further selective advantage. Foam trapping – to prevent high suspended solids (SS) carryover in the final effluent – exacerbates these problems.

To break this vicious cycle, the foam clearly needs to be removed. Various methods have been tried over the years with varying degrees of success. These include those listed below: Chlorination, or use of another oxidising agent, especially in the form of surface sprays; Dosing of Aluminium salts; Use of selectors; Use of scum traps of various designs

These methods vary in their level of effectiveness, and very often good results are synonymous with high costs and / or a high level of operator input. For these reasons, effective foam control in a problematic plant is seldom sustained.

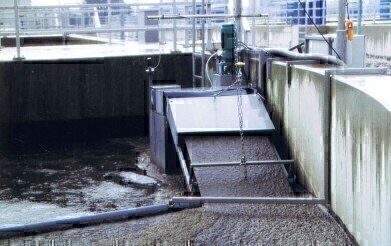

Although not widely marketed, a highly effective foam removal device has been in use on the Continent for well over 10 years. Not only does this innovative piece of equipment remove up to 80m³ or more foam per day and dewater it to 3-6% dry solids, but it can do so continuously and at very low operating cost. Such is its ingenuity and effectiveness, that it was awarded the coveted Ernst-Kuntz prize in 1998.

Introduced by Corgin to the UK in 2007, the Foam Skimmer has understandably generated significant interest, both from industry and from all of the UK wastewater companies.

By removing surface foam on a continual basis, the Foam Skimmer tackles much of the root cause of foam-causing filaments. This includes removing their foodsource (surface FOGs, dead cell material and septicity), their preferred environment and their ability to reseed.

Visual improvements often show within days, followed by profound effects on plant performance. Improvements vary from plant to plant, but benefits such as increased aeration efficiency, improved settlement / lower SVI’s reduced sludge wastage, reduced SS in final effluent, and overall plant performance improvements have all been experienced.

Events

WEATHER • CLIMATE • WATER / EARTH OBSERVATIONS / GREEN ECONOMY

Oct 29 2024 St. Petersburg, Russia

Oct 30 2024 Hong Kong

Nov 05 2024 Toronto, Canada

Nov 06 2024 Ho Chi Minh City, Vietnam

Nov 12 2024 Valencia, Spain

..jpg)