Green Energy

Nitrogen as a utility gas and feedstock for green ammonia

Dec 05 2023

For several years, attention has focused on green hydrogen as a clean energy vector. Produced on electrolysers from renewable electrical power generated by wind, solar or hydro schemes, green hydrogen has a very low carbon footprint.

Many of the largest green hydrogen electrolyser schemes that have been proposed worldwide will convert the green hydrogen to green ammonia for cost-effective shipping to international markets. Ammonia is derived from hydrogen through reaction with nitrogen, sourced from air, in the Haber Bosch process.

Conversion of hydrogen to ammonia adds cost at the production location but means that ammonia, rather than hydrogen can be shipped to the end-user destination thereby saving costs in the supply chain.

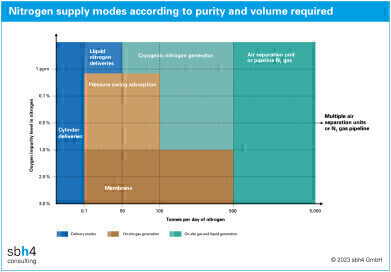

Nitrogen is fundamental utility gas for electrolysis and an essential feedstock for ammonia production. However, the scale and purity of nitrogen supply differs according to the application. Choosing the best-fit supply mode is essential.

Nitrogen supply options

Nitrogen can be supplied to the process in a variety of ways, depending on the scale required. In an industrial scale, cylinder gas deliveries would be impractical. The purity would be ideal, but the volume of nitrogen required is far more than can economically be delivered through this supply mode. Liquid nitrogen deliveries would also offer a suitably high purity but may also fall short of the economic threshold for merchant liquid nitrogen deliveries.

On-site nitrogen generation using a membrane may be able to provide the required volumes for a typical ammonia process. However, membranes do not achieve a very high nitrogen purity and the argon and oxygen impurities would need to be purged from the ammonia synthesis loop, resulting in energy losses.

Nitrogen generation using an air-fed pressure swing adsorption (PSA) system may be appropriate to yield the desired purity and flowrate. However, there is no option to generate liquid nitrogen from the PSA unit to store as a backup if the PSA is not operating.

The ideal choice may be an on-site cryogenic nitrogen generator. It can provide a high volume of high purity gaseous nitrogen to the ammonia synthesis process and may simultaneously produce liquid nitrogen which can be stored in a cryogenic vessel on-site. If required as a backup to the cryogenic nitrogen generator, liquid nitrogen from this storage can be vaporised and fed to the ammonia synthesis loop.

Nitrogen generators use a cryogenic process that is a simplified version of a full air separation unit (ASU). Unlike the ASU, nitrogen generators are not designed to produce oxygen and argon as co-products. The focus on nitrogen reduces the specific power requirement, simplifies operation, and reduces the plant capital cost compared to an equivalent nitrogen flow derived from the more complex ASU.

Nitrogen as purge gas for hydrogen electrolysers

Electrolysis splits water to create oxygen, in addition to hydrogen. In the PEM and AEM electrolyser types, these two gases are separated by a membrane. In alkaline electrolysers, both gases are present together, dissolved in the lye electrolyte that circulates around the electrolyser.

During operation with variable renewable power, as the electrolyser ramps down with reduced power availability, the oxygen concentration in the hydrogen gas increases. Safety management systems in the electrolyser to prevent the hydrogen concentration in the oxygen rising to a dangerous level. When activated, these safety systems flood the electrolyser with inert nitrogen gas. The lower flammable limit (LFL) of hydrogen in pure oxygen at atmospheric pressure and 20 °C is 4%. A nitrogen purge may be initiated at 2% or 2.5%.

Smaller electrolysers of less than 1MW capacity can use compressed nitrogen cylinders as a store of nitrogen. Mid-sized units up to 100MW may need a larger quantity stored on site as liquid nitrogen. It can be vaporised to gaseous nitrogen when used.

For a GW-scale green hydrogen alkaline electrolyser system working with a variable or intermittent renewable power source, there could be several occasions per year where the system may need to shut down and initiate a nitrogen purge. At GW-scale operation the amount of nitrogen required in these events may justify onsite nitrogen generation using PSA or cryogenic technique.

Nitrogen as a feedstock for green ammonia

Ammonia is readily liquefied, and, in this state, it has a volumetric energy density 50% higher than liquid hydrogen. The reduced shipping costs of liquid ammonia, compared to liquid hydrogen mean that capex and opex savings from shipping can be directed to the ammonia conversion facility. For long distances, such as the Australia to Europe route, liquid ammonia is the most cost-effective mode of green hydrogen transportation.

One of the attractions of using ammonia as a fungible energy vector is that it is already a globally produced and traded commodity. Worldwide grey ammonia production is around 185 million tonnes per year.

Traditionally, ammonia plants have introduced air to the ammonia synthesis loop to bring in the required nitrogen. Using pure nitrogen instead of air means there is no oxygen circulating in the ammonia synthesis loop. This minimises energy losses and reduces the required plant size, resulting in opex and capex reductions. In recent years small to medium ammonia plants have tended to use a pure nitrogen feed from an onsite nitrogen generator.

The inputs required to operate a nitrogen generator are electrical power, cooling water and ambient air. Using renewable electricity, the operation of a nitrogen generator can be fully sustainable. For the future generation of green ammonia projects, nitrogen generators will be ideal to supply the required green nitrogen to react with green hydrogen to produce green ammonia.

Events

IWA World Water Congress & Exhibition

Aug 11 2024 Toronto, Canada

Aug 25 2024 Stockholm, Sweden and online

Sep 03 2024 Mexico City, Mexico

Sep 03 2024 Mexico City, Mexico

Sep 03 2024 San Diego, CA, USA