-

The Biogrinder from BHS-Sonthofen accelerates the generation of biogas and increases the gas yield.

The Biogrinder from BHS-Sonthofen accelerates the generation of biogas and increases the gas yield. -

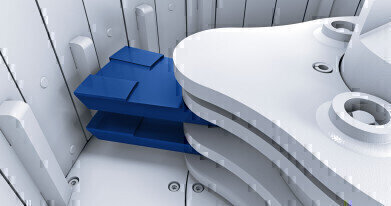

The new version of the Biogrinder is fitted with a disk rotor and stainless-steel components.

The new version of the Biogrinder is fitted with a disk rotor and stainless-steel components. -

The Biogrinder’s new design stands out thanks to its particularly high degree of flexibility and improved durability.

The Biogrinder’s new design stands out thanks to its particularly high degree of flexibility and improved durability.

Green Energy

BHS-Sonthofen launches a new version of the Biogrinder

Nov 24 2020

The new, completely redesigned Biogrinder from BHS-Sonthofen ensures that biogas is generated efficiently. The machine for biomass processing is now fitted with a disk rotor and stainless-steel components, making it stand out for its durability and flexibility.

Biogas is produced by microorganisms during fermentation. BHS-Sonthofen’s customers use the BHS Biogrinder of type RGB in their biomass processing plants to process biological materials for the fermentation process as efficiently as possible. “The more shredded the material is, the greater the number of contact surfaces the microorganisms have to attack, meaning biogas is generated even more efficiently,” explains Reinhold Jäger, Area Sales Manager in BHS-Sonthofen’s Recycling and Environment division. Energy-rich plants are subject intensive mechanical pre-processing in the Biogrinder. As a result, the gas generation process is accelerated and the fermentation process is stabilised.

The new, redesigned Biogrinder, which is available now, offers the user advantages in terms of improved durability first and foremost. “We are essentially talking about two innovations here,” says Jäger. “The first is that the rotor has a modular design. This means that the previous two-stage rotor has been replaced with a disk rotor. Each individual level can be replaced flexibly, depending on wear, while the base unit remains intact for a very long period of time.”

The second innovation – the extensive use of stainless steel – also boosts the durability of the machine. “The processed plant material is obviously in a state of decay,” says Jäger. “This decay causes acids to form that corrode the ferrous metals. The corrosion then amplifies the abrasive wear process. All of the machine’s components that come into direct contact with the material are now made of stainless steel.” This applies to the inner linings in particular, such as the rotor, side walls or inlet and outlet. The stainless steel prevents corrosion, extending the wear time considerably.

This makes the continuously operating Biogrinder even more robust. The proven machine still boasts all of its previous customer advantages. The Biogrinder (type RBG) is easy to operate and maintain. Even feed materials that are considered difficult or impossible to recycle can be processed with the Biogrinder. Plus, the Biogrinder consumes less electricity in comparison to other biomass crushers.

Events

Apr 22 2024 Hannover, Germany

Apr 23 2024 Kuala Lumpur, Malaysia

Apr 24 2024 Sao Paulo, Brasil

May 05 2024 Seville, Spain

May 13 2024 Munich, Germany