Air Clean Up

Cryogenics for CO2 emissions reduction

Jan 20 2023

Author credit: Stephen B. Harrison, sbh4 consulting

CCTUS refers to carbon dioxide (CO2) capture, transportation, utilisation, and storage. Moving large amounts of CO2 cost effectively can be achieved through liquefaction of the CO2. Cryogenics makes CO2 compact for transportation and storage. Gaseous CO2 at atmospheric pressure and ambient temperature requires 588 times more volume than liquid CO2.

Cryogenic CO2 capture technologies are ideal where liquid CO2 distribution will be required to the utilisation or sequestration location. This will be the case where the CO2 is destined to be used in food, beverage, or other industrial gases applications.

It is also likely that liquid CO2 distribution for carbon capture and sequestration (CCS) projects will be required for many years, since almost no CO2 pipeline infrastructure exists today. For example, the Northern Lights CCS project (which will permanently store CO2 emissions from a waste to energy plant and Norcem’s Brevik cement plant in Norway) will use liquid CO2 distribution. Ships will transport liquid CO2 from the capture locations to the underground injection location, offshore in the North Sea.

Direct liquefaction of mixed gases is difficult. For example, when CO2 is present in a mixture with nitrogen, the nitrogen is incondensable at the temperature at which the CO2 can be liquefied. This means that the CO2 liquefier heat exchanger becomes shrouded with nitrogen gas and there is no longer any contact with the CO2 gas to be liquefied. The potential solution would be to vent nitrogen gas from the system, but the vent gas would also contain CO2. Much of the CO2 would be vented and lost, meaning this is rarely a viable solution.

On the other hand, direct liquefaction of very pure CO2 is viable. In this context, ‘very pure’ would typically a purity greater than 98%. Biogenic CO2 released from bioethanol fermentation or brewing produces CO2 at this purity.

Direct liquefaction of CO2 from fermentation broths requires drying of the CO2 prior to liquefaction. This is essential to avoid formation of solid ice particles within the CO2 liquefier. It also ensures that the CO2 product is suitable for commercial applications in the food and beverage sector or for metallurgical welding applications.

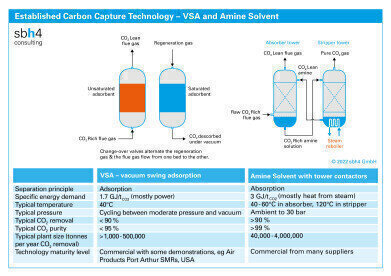

Hundreds of small-scale direct CO2 capture and liquefaction installations exist worldwide, mostly at breweries. Similar technology is used to remove CO2 during upgrading of biogas to biomethane. But, in this case separation of the methane and CO2 is required prior to liquefaction. This is often achieved using a membrane or amine solvent CO2 capture process.

It is only recently that technology has been developed for the direct liquefaction of CO2 from lower concentration CO2 streams. The US start-up Sustainable Energy Solutions, now part of Chart Industries, has developed the Cryogenic Carbon Capture (CCC) process during the past decade.

CCC does not actually use direct liquefaction of CO2, rather it relies on direct sublimation of CO2 gas to solid CO2. Hence it can capture CO2 from dilute flue gas streams. After the solid CO2 has been formed, it is dissolved into liquid CO2. The product is high purity liquid CO2.

The CCC process relies only on electrical power for gas blowers and compressors for its operation. There is no heat input required. The implication is that it is aligned to operation with renewable electricity, meaning that no CO2 emissions are created from capturing the CO2.

A further advantage of the CCC technology is that it sufficiently robust to treat ‘dirty’ post-combustion flue gases that contain oxides of sulphur or nitrogen. This means that it is ideally suited to capture CO2 from emissions generated from burning coal, waste, or heavy fuel oil. In contrast, amine-based absorption and molecular sieve adsorption processes for CO2 capture are very sensitive to sulphur impurities, meaning that a pre-purification stage would be required.

CO2 liquefaction relies on mechanical refrigeration and heat exchange. It is a different to the cryogenic liquefaction process used on air separation units, where expansion of the air itself on a turbine is used to generate the cold energy required for liquefaction of the air.

Liquid CO2 storage tanks are constructed of carbon steel and insulated with polyurethane foam. This also differs from cryogenic storage of liquid oxygen, argon and nitrogen which are much colder. They require an austenitic grade of stainless steel for the tank and vacuum insulation to prevent vaporisation of the cryogenic liquid.

Events

IWA World Water Congress & Exhibition

Aug 11 2024 Toronto, Canada

Aug 25 2024 Stockholm, Sweden and online

Sep 03 2024 Mexico City, Mexico

Sep 03 2024 Mexico City, Mexico

Sep 03 2024 San Diego, CA, USA