Water/Wastewater

Ecological solution for wastewater treatment

Mar 03 2009

BPC (Israel) has pioneered a new, powerful, ecological solution for a range of waste water treatment challenges: ACT – Automatic Chemostat Treatment. This trailblazing “green” process is easy to modify and can be used in various sites, including oil refineries, oil storage farms, drilling sites, marine ports, contaminated reservoirs and storage tanks.

Based on patented innovations, the process is flexible and easy to integrate, fully automated, controllable and significantly more efficient than current practices. The results are a virtually sludge-free output of water which can be returned directly into the environment or processed further.

The Innovative Concept: Automatic Chemostat Treatment (ACT)

The scientific concepts behind ACT are the application of an appropriate bacterial cocktail for a given type of polluted water, and an innovative chemostat. The process is maintained in a balanced state of bacterial growth and organic compound degradation.

Thanks to the low concentration of bacterial cells, no aggregates are formed, and each bacterium acts as a single cell which increases the surface available for the process and enables biodegradation at a much higher efficiency.

The ACT operates as a continuous flow reactor without using activated sludge. The bioreactor can thus be applied on site while using available infrastructure with high flexibility for modulation of the process saving dramatically in operational and maintenance costs.

Unmatchable Benefits

The advantages of the ACT are immediate:

ACT simplifies the process by reducing bio sludge and chemical usage as well as reducing black sludge creation. ACT’s flexibility and modularity enables to handle low and high capacities and contamination, to be used for fresh and salt water as well as to be easy modify and Increase capacities. Output is virtually sludge-free, meeting strictest disposal standards. The process does away with shipping of drainage water and leftover sludge.

Full Control from Any Point for Every Point

Nothing is left to chance when BPC’s Automatic Chemostat Treatment (ACT) is applied. The operator can at any point in time, via various interaction channels, from a control center, a laptop or a cellular phone, see the real-time status picture, receive real-time sound and SMS alerts, and take action. Supervisors can receive automatic reports, update environmental offices on-line, and most importantly, effectively avoid catastrophes. Crises management is vastly simplified with BPC’s monitoring technology.

The fully automated system is comprised of a variety of on line sensors which feed the control unit information on various parameters such as: TPH, nitrogen, dissolved oxygen, TOC and temperature. The controller ensures to maintain optimum process balance between the flow rate, bacterial growth, additives and organic compound degradation.

Unique Pilot Offering:

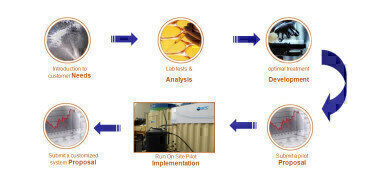

With its process already fully operational, BPC offers potential customers chance to world experience its remarkable technology through a skid mount pilot system. At minimal cost, clients can experience how the solution is adapted to their site, and realize the multiple benefits in advance, of deciding on full installation. Backed by continuous laboratory tests and technical services from BPC, the pilot system delivers constant feedback in real-time, so that any challenges can be addressed at this initial stage. The pilot system is thus an ideal introduction to a process that already is dramatically changing the concept of waste water treatment.

Events

WEATHER • CLIMATE • WATER / EARTH OBSERVATIONS / GREEN ECONOMY

Oct 29 2024 St. Petersburg, Russia

Oct 30 2024 Hong Kong

Nov 05 2024 Toronto, Canada

Nov 06 2024 Ho Chi Minh City, Vietnam

Nov 12 2024 Valencia, Spain

..jpg)