-

Glass tempering

Glass tempering -

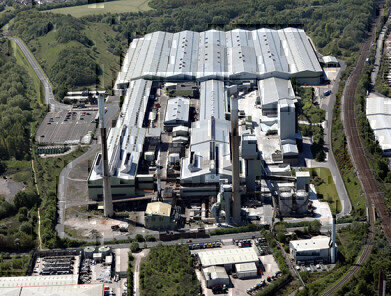

Pilkington St-Helens

Pilkington St-Helens

Air Clean Up

Capturing geogenic CO2 from glass making

Aug 16 2021

Author credit - Stephen B. Harrison and Allegra Cresswell-Turner, sbh4 consulting

During glass making, like lime, cement and refractory products making, the release of geogenic carbon dioxide (CO2) is unavoidable. The sands and minerals used in these processes contain CO2, which is released during glass melting or rock calcination. These mineral processing industries must live with the fact that geogenic CO2 is generated, even if heating from renewable electrical power or hydrogen is used to replace fossil fuel fired burners. However, there are many things that can be done to mitigate CO2 emissions to the atmosphere. Decarbonisation may be ‘difficult’ but will be possible. Established technologies exist, and more are on the horizon to enable cost-effective decarbonisation of glass making.

Capturing carbon dioxide gas emissions

There is no alternative to the sand and minerals used for glass making, they must be a specific type, and geogenic CO2 is released from the minerals during the melting process. There are several existing methods to reduce emissions, such as improving energy efficiency, or using recycled glass with the raw materials. Even if the glass melting heating process is decarbonised, for example with electrical heating from renewable power, geogenic CO2 will still be released during the glass melting. Part of the decarbonisation solution in glass making and other mineral processing industries must therefore include ‘carbon capture’.

A range of technologies for capturing the CO2 emissions exists such absorption into an amine type solvent, or adsorption onto solid sorbents that have a high affinity for CO2. Mineralisation of the CO2, for example through combination with ultramafic rocks, is another way to capture CO2 emissions.

As an alternative to traditional carbon capture technologies, the UK based company C-Capture has developed an inexpensive carbon capture process that uses less energy than conventional technologies. Their chemistry uses a different solvent to the traditional amine-based technology and through smart engineering it operates at low temperatures and pressures to minimise the capital cost of the equipment and reduce heat losses. Their process will be piloted at the UK’s Drax Power Station to be one of Europe’s largest bio-energy carbon capture and storage schemes.

C-Capture, based in Leeds, has announced that it will work with Pilkington United Kingdom Limited to investigate the feasibility of using their technology to capture CO2 emissions from glass production. This partnership has been given funding through Innovate UK’s Sustainable Innovation Fund.

Glass production in the UK has a long history, with companies such as Pilkington’s at St Helens operating since 1826. The glass making industry in the UK has managed many transitions over the decades, including the implementation of modern tin-bath float glass technology and the conversion of burners for glass melting from coal to natural gas. The next transformation will be to decarbonise operations and reduce CO2 emissions to air.

Carbon capture and storage, or utilisation

In some cases, captured CO2 can be utilised, in other cases it may need to be injected underground for permanent storage in a CCS scheme. In the UK, several CCS schemes are being considered for government support and implementation such as HyNet North West, The Acorn Project and Zero Carbon Humber.

Commercial applications for captured CO2 include combination with ammonia for urea fertiliser production, freezing food and production of carbonated beverages. Also, and with great relevance today, CO2 can be used to create dry ice, which has been used expansively throughout the current Coronavirus pandemic in the vaccine supply chain, including airfreight from manufacturing sites, road transportation and short-term storage at vaccination sites.

Working together for planetary health

The glass making industry undoubtedly shares the aspiration to decarbonise with many other sectors and lessons can be shared across the various mineral processing sectors. In the European cement industry, there are many pilot projects for decarbonisation of post-combustion and geogenic CO2 emissions underway.

Without doubt, capital will need to be invested, additional energy will be required with the result that glass products may be marginally more expensive. But these are the costs of planetary health that must be borne universally as we move closer to becoming a net-zero society.

Events

WEATHER • CLIMATE • WATER / EARTH OBSERVATIONS / GREEN ECONOMY

Oct 29 2024 St. Petersburg, Russia

Oct 30 2024 Hong Kong

Nov 05 2024 Toronto, Canada

Nov 06 2024 Ho Chi Minh City, Vietnam

Nov 12 2024 Valencia, Spain