Air Clean Up

New Solution Turns Exhaust Air into a Source of Energy

Jun 16 2012

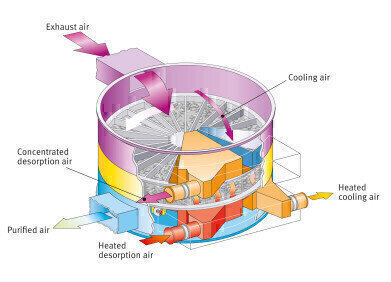

Until now, the concentration of exhaust air containing solvents using the Eisenmann (Germany) adsorption wheel has simply been a preliminary, cost-efficient step towards providing clean air. But Eisenmann has recently developed systems for employing the energy-rich concentrate in decentralised industrial power plants – as a partial substitute for natural gas and oil.

The Eisenmann adsorption wheel, deployed in industrial facilities, turns large quantities of exhaust air with a low solvent content into small volumes with high concentrations. Usually, the concentrated pollutants are then incinerated in a thermal or regenerative thermal oxidiser (TO/RTO). The benefit: due to the high concentration of energy-rich solvents, only a small amount of fossil fuels is needed to burn the pollutants. This saves manufacturing companies operating costs.

But what if the energy content in concentrated exhaust air could be used in other ways? Working with a customer in manufacturing, Eisenmann engineers have developed a system by which desorption air coming out of the adsorption wheel can be fed into an existing boiler, where it can be incinerated together with the natural gas. “In this concrete scenario, our customer saves up to 20 cubic meters of natural gas per hour,” reports Michael Breuning, Sales Manager for Exhaust Air Treatment at Eisenmann Anlagenbau. He continues: “With three shifts per day and 50 work weeks per year, and a natural gas price of five euro cents per kilowatt-hour, this model can generate annual savings of up to 60,000 euros.” As with the destruction of pollutants in an oxidizer, this configuration meets all the requirements of the German federal Emission Protection ordinance (BImSchV).

Boilers are not the only decentralised power plants that can reap economical benefits from energy-rich desorption air. On behalf of a different customer, Eisenmann specialists have succeeded, by means of additional cleaning and cooling, to treat concentrated exhaust air so that it can be incinerated in a combined heat and power (CHP) plant. Here, too, what was originally a waste product can be used as a substitute for the fossil fuel natural gas. “Thanks to our combination of processes, we can feed in up to 100 kilowatts per hour into the CHP plant. This reduces the consumption of natural gas by up to ten cubic meters per hour,” says Breuning.

Events

May 05 2024 Seville, Spain

May 13 2024 Munich, Germany

May 23 2024 Beijing, China

May 23 2024 Beijing, China

Jun 10 2024 Algiers, Algeria