Water/Wastewater

System for High-flow TOC Reduction

Aug 15 2012

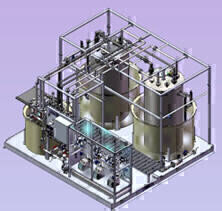

Siemens Water Technologies (USA) have recently introduced their Vanox Advanced Oxidation Process (AOP). This is a high-flow solution aimed at Total Organic Carbon (TOC) reduction in semiconductor manufacturing applications. This system has been designed to meet all International Technology Roadmap for Semiconductors (ITRS) requirements for the future by having a capacity to treat hundreds of gallons per minute. The Vanox system can consistently reach TOC levels of 0.5 ppb whilst treating seasonal TOC variations in water. This is an important performance measurement, as organic carbon elevations above 1.0 ppb can directly affect the manufacturing process, impacting product yields at every stage where the product comes in contact with water.

Research suggests that the species of a TOC is as important as the amount of it. The Vanox AOP system aims to attack the TOC species that have the greatest impact on microelectronic productions. Such productions include urea, which historically have proven difficult to remove using conventional methods. The Vanox AOP system removes and/or controls urea primarily associated with THMs (trihalomethane) such as chloroform, which is generated as a byproduct from the use of chlorine. The system also addresses IPA, another difficult-to-control primary organic that can require more involved treatment.

The Vanox AOP solution offers the ability to scale systems for future flow and TOC demands through a modular design coupled with the process ability to set the TOC effluent where the technology node requires it to be.

The Vanox system will offer 365 day/24 hour uptime. The platform uses only the power that is required to meet demand meaning energy consumption is reduced By utilising a suite of customised analytical measurement tools, the Vanox AOP system offers continuous process control and access to streaming process data for constant tracking of the system and the environmental parameters it is responding to.

Events

May 05 2024 Seville, Spain

May 13 2024 Munich, Germany

May 23 2024 Beijing, China

May 23 2024 Beijing, China

Jun 10 2024 Algiers, Algeria