Waste Management

£100 Million Renewable Chemical Scheme

Jan 31 2011

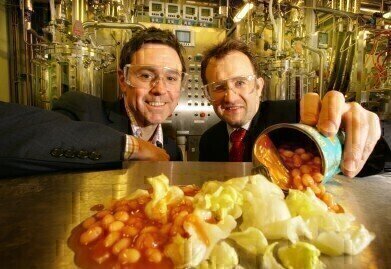

A renewable chemical sector entrepreneur has unveiled ambitious plans to develop the UK’s first manufacturing facility producing industrial chemicals from domestic and commercial waste.

Solvert Limited will use advanced biological fermentation processes to produce renewable n-butanol, acetone, hydrogen and electricity from wet biodegradable waste. Not only environmentally-friendly, the process utilises a feedstock which other new industries such as waste-to-energy plants cannot use effectively.

“The current drive within the UK is to divert waste away from landfill sites into more productive uses – such as feedstocks for other processes,” said Solvert’s CEO Kris Wadrop.

“Organic waste, such as spoilage from supermarkets or the leftover food from our kitchens at home and in restaurants, holds immense potential for conversion into valuable chemicals to replace those produced from crude oil.

“At the moment, hydrogen, acetone and n-butanol come from non-renewable petrochemical sources and there are no UK producers. N-butanol and acetone are currently imported into the UK from Western Europe and the USA.

“A significant market for these chemicals already exists in the North East of England as well as other parts of the UK, and more customers from further afield are also looking for a greener alternative to products derived from crude oil. These products form part of our daily lives as they are used extensively to produce paint or plastics such as Perspex.

Events

WEATHER • CLIMATE • WATER / EARTH OBSERVATIONS / GREEN ECONOMY

Oct 29 2024 St. Petersburg, Russia

Oct 30 2024 Hong Kong

Nov 05 2024 Toronto, Canada

Nov 06 2024 Ho Chi Minh City, Vietnam

Nov 12 2024 Valencia, Spain