Hazardous Waste

Processing Technology for Radioactive Wastes

Oct 25 2012

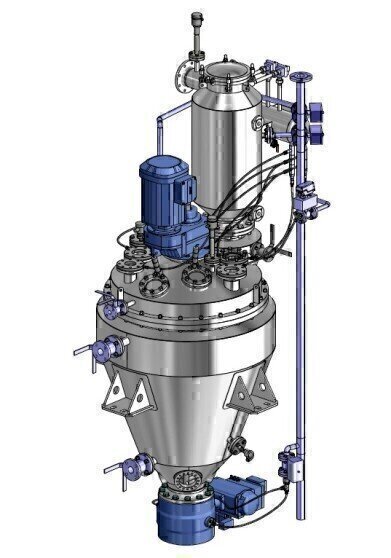

For 20 years now, AVA (Germany) has been delivering innovative mixers, dryers, and systems for environmental and processing technologies. The treatment of highly contaminated materials has always been one of their core competences.

For more than 10 years, AVA Technology has been in the industry for processing of radioactive wastes. The application of AVA mixers and reactors may be divided into two main sectors:

The most frequent task is the vaporisation of radioactive sewages and sludges. Batches of these sewages and sludges are heated in a conical dryer, thus evaporating the water content.

Due to the low solids content and the volume reduction after certain drying periods, the dryer may be filled repeatedly in order to concentrate the product batch. In a downstream condensation unit, the evaporated water - which at that point is only slightly radioactive – is collected and conducted to a special water treatment plant.

The concentrated, highly radioactive residue may either be barrelled directly, or mixed with cement in a downstream mixer, thus being bound without eluates. For this process, also referred to as cementation, special mixers with a fully automated self cleaning system are used. This technique – having its origins in the pharmaceutical industry – has been refined by AVA for this particular application. The resulting waste product is barrelled and cures in place.

The handling of radioactive material places particularly high demands on the design of the machines. Some typical design features for radioactive applications are as follows:

First to mention is the installation of the drive motor outside the product space by means of a special prolonged agitator shaft. In order to prevent contamination of the surroundings, these systems are mostly entirely welded. Another option is the automated self cleaning system mentioned above. The sealing of the shaft is always a crucial issue: AVA‘s conical dryers have a great technological advantage, as the sealing itself does not come into contact with the contaminated medium. Generally, the sealing is implemented using double-acting mechanical seals with a sealing liquid system monitoring radioactivity.

Apart from the core components of mixers, dryers and reactors, AVA also provides entire systems and turnkey plants. On demand, the entire range of services will be provided all inclusive: from the batch to the automated barrelling system, pursuant to the containment demands as a matter of course.

Events

WEATHER • CLIMATE • WATER / EARTH OBSERVATIONS / GREEN ECONOMY

Oct 29 2024 St. Petersburg, Russia

Oct 30 2024 Hong Kong

Nov 05 2024 Toronto, Canada

Nov 06 2024 Ho Chi Minh City, Vietnam

Nov 12 2024 Valencia, Spain