Water/Wastewater

Siemens chooses Watercare International for Severn Power

Nov 06 2009

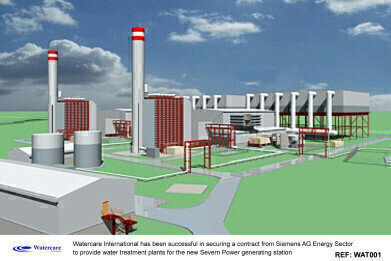

In the face of strong international competition, Watercare International (UK) has been successful in securing a prestigious contract from Siemens AG Energy Sector to provide the boiler make-up and condensate polishing water treatment plants for the new Severn Power generating station, owned by DONG Energy.

The boiler make-up plant, which will achieve the stringent make-up water requirements specified by the VGB standards, is rated at 16 m3/h. Each of the project’s two condensate-polishing plants has a capacity of 440 m3/h, and whilst operating in the ammonia cycle, will deliver polished condensate water with low levels of sodium, again in line with VGB standards.

“Naturally, we’re delighted to have won this important contract,” said Chris Russell, Managing Director at Watercare International. “We believe that our success in doing so was due, in no small part, to our proven experience in providing efficient, dependable and cost effective solutions for a wide range of industries where large volumes of process-critical water are required.”

Richard Tyreman, Project Director of Severn Power said: “Severn Power has been specifically designed to minimise its environmental impacts, and a key aspect of this is to ensure that no water is taken from, nor discharged into, the river Usk.”

The Severn Power generating station is an 850 MW CCGT (combined cycle gas turbine) power station that is being built on the site of the former Uskmouth A power station in South Wales. The new station has been specifically designed to have minimum environmental impact.

This has led to the adoption of super-critical (once-through) boiler plant and air-cooled condensers. Installations of this type benefit greatly from being used in conjunction with a condensate polishing system that can consistently deliver water with extremely low sodium content.

To achieve the required performance, Watercare International is supplying an externally regenerated condensate polishing system with resin transfer between two cartridge-filtration, mixed-bed operator condensate polishing sets and a common multiple vessel regeneration plant. This condensate polishing plant, which operates in the ammonia cycle, is the first of its kind to be built in the UK for over 20 years.

The boiler make-up water treatment plant for the project, which takes its input from a challenging and variable feed water supply, incorporates media filtration, a reverse osmosis membrane system and ion-exchange polishing technologies.

Events

May 05 2024 Seville, Spain

May 13 2024 Munich, Germany

May 23 2024 Beijing, China

May 23 2024 Beijing, China

Jun 10 2024 Algiers, Algeria