Water/Wastewater

Reducing Effluent Treatment Costs at Frozen Food Plant

May 13 2010

Micromac Filtration (UK) has successfully completed a major effluent treatment system design and installation project at North East Lincolnshire based Headland Foods. One of the UK’s leading suppliers of frozen ready meals, Headland Foods produces over two million meals each week from two sites in North East Lincolnshire and North Wales.

Selected as Headland Food’s design and technology partner by the company’s Engineering Manager, Iain Robinson, Micromac Filtration has completely re-designed and upgraded the plant’s effluent treatment infrastructure. As a result, Robinson reports that already, Headland Foods are benefiting from lower costs associated with effluent treatment, and they have complete confidence that all their effluent discharges meet with consent limits applied by Anglian Water.

Replacing an under sized run-down screen that had a tendency to block requiring manual clearing, often at night, Micromac has designed and installed a system with a new larger run down screen with a spray wash bar which helps prevent blocking. Also, positioning the run down screen at ground level made any maintenance tasks straightforward. A Dissolved Air Flotation (DAF) unit is very effective at removing suspended solid matter and a centrifuge dries the sludge from the DAF unit and reduces the waste volume for disposal.

The system was installed on time and within budget. Headland Food reports that already the new effluent treatment is working significantly more efficiently and reliably than its predecessor.

“We appointed Micromac on the basis of their competitive pricing combined with the technical proficiency and supportive nature of their staff,” explains Iain Robinson. “The work carried out by Micromac has met all of our expectations.

“The technical support that we received from the Micromac team has been first class – personally, I feel that I’ve learned a lot about effluent treatment during this project. The DAF unit is a very effective tool and is well suited to our needs,” he added.

Headland Foods are currently looking at a water re-use project on their Grimsby site and would welcome the opportunity to work with Micromac Filtration again. “I have recommended Micromac to several other companies – I can say no better than that,” concludes Iain Robinson.

Technology background – Dissolved Air Flotation Unit

Micromac Filtration’s DAF system is designed to clarify liquids that are high in contaminants. It reduces chemical oxygen demand, suspended solids, fats, oil and grease in wastewater by up to 95 per cent.

The DAF system is entirely UK designed and manufactured. This stainless steel constructed unit is almost half the capital cost of rival systems. Micromac use their own installation team on all UK-based projects.

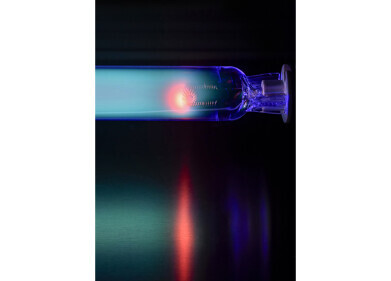

Micromac’s DAF unit injects a coagulant and flocculant in to the effluent stream in order to coagulate the particles. Then, a pressurised dissolved air saturation system injects a continuous stream of micro-bubbles into the DAF flotation tank. The bubbles attach to the particulates, causing the coagulated particles to float. These are skimmed off the surface for disposal and the clarified water exits over a weir.

This approach has a number of advantages for industrial application. The system is freestanding, has a very compact footprint and has very few moving parts. Power consumption is low and the system is easily maintained with minimal operational outages.

Key applications for Micromac Filtration DAF units include food processing – especially dairies - industrial water processes, sewage treatment, recycling, petrochemicals, breweries and agriculture.

Micromac installed Helixor Aeration systems in the effluent treatment system’s Balance Tank with the intention of mixing the effluent, making it more uniform and easier to process. The Helixor facilitates efficient oxygen transfer and complete mixing conditions. It requires minimal capital costs thanks to its simplicity of installation and start-up. The absence of any moving parts underwater results in significant savings in operating and maintenance costs.

Events

May 13 2024 Munich, Germany

May 23 2024 Beijing, China

May 23 2024 Beijing, China

Jun 10 2024 Algiers, Algeria

Jun 10 2024 Frankfurt, Germany