Water/Wastewater

Turning Mine Water into a Useful Resource

Jun 09 2010

A new water treatment system, the first to be used in a North American coal mine, is being implemented by CONSOL Energy Inc. in one of the nation’s largest coal mines. The Buchanan No. 1 coal mine in Oakwood, USA, will receive GE’s advanced filtration membranes and thermal water treatment technology to treat the mine water, enabling about 99 percent of the water to be reused in part at the company’s preparation plant facility.

When in operation, the new system will significantly reduce the volume of mine water that must be managed. Further, it will reduce freshwater demand, as the processed water coming out of the system can be used at the mine’s preparation plant facility, reducing the need to obtain water from other sources. The salt that naturally occurs in the mine water will be removed through the filtration process.

The Buchanan mine is one of the nation’s largest underground coal mines, larger in area than some small cities. In 2009, the CONSOL Energy mine produced 2.84 million clean tons of coal and 71.45 billion cubic feet of associated coal bed methane gas from its Virginia operations.

“Our goal is not only to help customers solve specific treatment problems, but to help them recognize and take advantage of opportunities to recover additional value,” said Steve Watzeck, president of engineered systems — water and process technologies for GE Power & Water. “GE offers extensive know-how gained from decades of global project experience, combined with innovative products and cutting-edge research. The result is a unique solution that hits the mark operationally, environmentally and economically.”

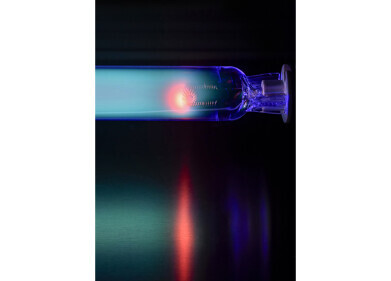

Part of an overall infrastructure upgrade expected to be completed by the fourth quarter of 2010, GE’s zero liquid discharge (ZLD) system is capable of treating up to 1,600 gallons of water per minute utilizing a combination of ultrafiltration, reverse osmosis, brine evaporation and salt crystallization technologies. In the process, dissolved minerals in the mine water, largely salt, will be left behind in a crystalline form. Mine operations will not be impacted during system installation. GE has teamed with building contractor Bowen Engineering Corporation on the project.

The system GE is providing to CONSOL Energy incorporates GE’s ZeeWeed* ultrafiltration technology, which employs hollow-fiber membranes to separate particles from water, and GE’s reverse osmosis separation technology, which removes dissolved impurities from water through the use of a semi-permeable membrane. The concentrated brine from these elements of the system is then treated by GE’s proprietary thermal evaporation, crystallization and drying ZLD technologies, which make up the heart of this integrated process.

Events

May 13 2024 Munich, Germany

May 23 2024 Beijing, China

May 23 2024 Beijing, China

Jun 10 2024 Algiers, Algeria

Jun 10 2024 Frankfurt, Germany