Water/Wastewater

The City of Beijing Uses the Technology From Poland’s BIOGRADEX to Manage its Ambitious Olympic Village Water Reclamation Project

May 20 2010

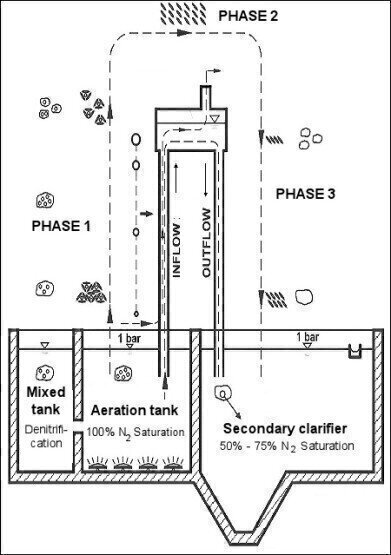

The wastewater treatment technology from BIOGRADEX (Poland) has over a decade of full-scale operating experience in Europe and Asia. It was developed by engineers from Elblag in Poland, and patented globally. The technology provides effective-year round Biological Nutrient Removal (BNR) with unparalleled low cost, minimal land use, and high treatment efficiency for existing and new activated sludge Waste Water Treatment Plants. The core of BIOGRADEX® technology is a unique process enhancement of BNR treatment by vacuum degassing of mixed liquor. The MLSS (mixed liquor suspended solids) is degassed in a low energy input BIOGRADEX® tower immediately after biological treatment and before secondary clarification. MLSS vacuum degassing results in major improvements of sludge settling, thickening and stabilization in clarifiers.

BIOGRADEX implemented the technology at Beijing’s Qinghe Phase II Wastewater Treatment Plant, which caters for the water-related needs of the residents of Northern Beijing, including the Olympic Village. It was built just in time for the 2008 Beijing Olympic Games and belongs to the most ambitious projects of this type in China. The Chinese client wanted to impress the world with the Olympic Village water reclamation project and the Polish technology was selected based on its technical parameters after a thorough review of available technology alternatives.

The installation was relatively simple, with limited construction and operating costs. The plant consists of four identical BNR bioreactor trains. There are 3 types of cells - anaerobic, anoxic and aerated in each bioreactor train. Anaerobic and anoxic cells are mixed-only cells using submerged mixers. Aerated cells have fine bubble aeration. Aeration blowers (air flow) control is based on dissolved oxygen concentration in the aerated cells. Mixed liquor from the bioreactors flow to rectangular clarifiers equipped with horizontal scrapers. In total, there are 30 secondary clarifiers. Combined flow from each of the two North and two South trains flow to 15 dedicated clarifiers. BIOGRADEX suggested to install the temporary inlet baffles for all of the 30 secondary clarifiers in order to adjust the secondary clarifiers influent conditions.

BIOGRADEX® installation consists of vacuum degassing towers (one per train), vacuum pumps and service water cooling systems. The technology allowed a consistent increase of mixed liquor concentration to 5,00 mg/L from approximately 3,000 - 3,500 mg/L without sludge carry over from secondary clarifiers. The converted trains’ treatment results are:

• TN (total nitrogen) 10 - 12 mg/L

• TSS (total suspended solids) < 10 mg/L

• NH3 (ammonia) < 1.0 mg/L

The following comparison table shows differences in treatment results before (2006 results) and after the installation of BIOGRADEX® technology (2008 results). Also shown are the differences in treatment results between the trains converted to BIOGRADEX® technology and the conventional (non-BIOGRADEX) trains. The estimated daytime flow rate through BIOGRADEX® trains was a stunning 120,000 m3/day. The estimated daytime flow rate through the South (non-BIOGRADEX®) trains flow was reduced to 90,000 m3/day.

|

South & North trains |

South trains (non-BIOGRADEX®) |

North trains (BIOGRADEX®) |

|

|

Time of measurement |

February-March 2006 |

February-April 2008 |

February-April 2008 |

|

Q Rate (flow) (m3/day) |

200,075 |

90,000 |

120,000 |

|

NH3 (ammonia) (mg/L) |

8.42 |

1.77 |

0.87 |

|

TN (total nitrogen) (mg/L) |

20.3 |

17.0 |

12.0 |

|

MLSS (mixed liquor suspended solids) (mg/L) |

3,191 |

3,441 |

4,550 |

BIOGRADEX from Poland hold patents from the European Patent Office (EPO), the United States Patent and Trademark Office (USPTO) and various national patent offices. The company was selected by the Polish Ministry of the Environment as one of the leading, innovative green technology companies from Poland, promoted by the government-managed GreenEvo project (Accelerator of Green Technologies).

Events

May 05 2024 Seville, Spain

May 13 2024 Munich, Germany

May 23 2024 Beijing, China

May 23 2024 Beijing, China

Jun 10 2024 Algiers, Algeria