Water/Wastewater

New Controller Allows UV Systems to Precisely Match Customers’ Requirements

Jun 25 2010

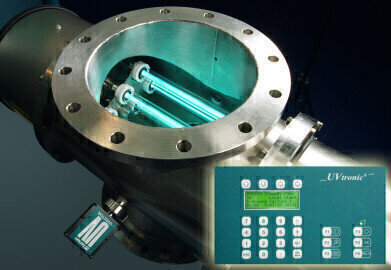

Berson’s (The Netherlands) new UV-Tronic+ V5 PLC controller links to a UV disinfection system’s SCADA control system and allows users to set up and manage the UV system’s operating parameters to exactly match their requirements. The latest version of Berson’s UV-Tronic controller range, the UV-Tronic+ V5 is based on a rugged industrial PLC and with an RS485-based Modbus interface.

Older versions of the UV-Tronic already had the capacity to control multiple streams and treatment chambers, a particularly useful feature where treatment plants may have variable water parameters such as flow or transmittance as it allows shutdown of individual UV chambers when not required, reducing power consumption.

The new UV-Tronic+ V5 has enhanced features which makes it possible to individually control the power level of up to six UV disinfection chambers simultaneously to suit the flow conditions for each stream, thus further minimising power consumption.

In addition, the controller can be programmed to calculate the required power setting depending on whether it is validated to DVGW*, UVDGM** or Berson’s default dose control settings. Software is currently being written which will also allow it to operate to NWRI*** parameters. The device can control conventional electro-magnetic ballas as well as Berson’s own electronic ballast.

Additional new features include greatly extended monitoring and control via Modbus, increased manual control functionality to ease maintenance and servicing, and the capacity to individually calibrate UV sensors when running in DVGW mode. A modem can also be used to provide remote monitoring and diagnosis and for software upgrades.

In addition, when UV monitors on the inner wall of the UV chamber register a fall in the UV level, the UV-Tronic+ V5 is designed to trigger automatic wipers on the quartz sleeves protecting the UV lamps. The wipers remove any built-up deposits on the sleeves, ensuring uninterrupted protection against microbial contamination. A major benefit of automated wiping means no chemicals are required for cleaning, an especially important feature when it comes to drinking water disinfection.

“The UV-Tronic+ V5 is a very useful feature of the Berson UV system,” comments Bob Clifforde, an Electrical Engineer at Cambridge Water in the UK who uses the new system. “By allowing us to control each UV chamber individually it not only greatly simplifies operations but has also reduced our operating costs.”

Berson UV is one of the few non-German UV system suppliers capable of providing a complete range of UV systems with capacities between 10 – 10,000 m3/hour, certified to the newest German DVGW norm, W294, Part 1, 2 & 3 – the highest standard currently possible in the world.

Events

May 05 2024 Seville, Spain

May 13 2024 Munich, Germany

May 23 2024 Beijing, China

May 23 2024 Beijing, China

Jun 10 2024 Algiers, Algeria