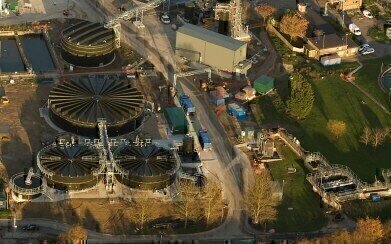

Water/Wastewater

Treating High-Strength Ammonia Wastewaters

Nov 26 2010

ACWA Services’ (UK) innovative AMTREAT® activated sludge process, a dedicated, cost-effective system for treating high-strength ammonia wastewaters, enables utilities to meet increasingly onerous discharge consent requirements for ammonia and total nitrogen.

High strength ammonia wastewaters are typically generated in sludge treatment processes. The AMTREAT® system is designed to operate at its optimum level when the influent liquor temperature is 25ºC and is effective between 20ºC and 35ºC, so it is ideal for the warm liquors that the sludge drying process generates. The relatively low temperature used gives the system a real advantage over competitor systems that require temperatures of 30ºC to 40ºC to work efficiently, generating significant energy penalties.

The AMTREAT® system can achieve full nitrification of effluent streams with ammonia concentrations of up to 3000mg/l, with typical ammoniacal nitrogen removal rates in excess of 97%. Although some competitor systems claim 25% energy savings by producing NO2 (nitrite) rather than the NO3 (nitrate) created in the full nitrification process, any cost savings are offset by the considerably larger power expenditure required to ensure the contents of the large tanks remain mixed for the longer retention time required.

ACWA Services Wastewater Process Manager, Dr Sarah Collins warns of a further issue: “In systems that claim as much as 30% less sludge production, the amount of sludge produced is likely to depend more on carbonaceous removal than the production of the bacterium, Nitrobacter (converting NO2 into NO3) – if less sludge is produced as a result of producing NO2, it would be infinitesimal as the amount of sludge produced from Nitrobacter is negligible in the overall picture.”

A typical AMTREAT® system consists of a balance tank with mixing system, a liquor blending system, followed by an anoxic tank to provide denitrification upstream of the AMTREAT® reactor. The anoxic tanks are optimally sized to ensure adequate denitrification without the severe cost penalties incurred by larger tanks. Dr Collins notes: “There is a careful balance between achieving denitrification and the size of the tank required. The AMTREAT® anoxic tanks are designed to ensure that this delicate balance is optimised. Larger tanks will achieve greater denitrification and release more alkalinity to the system, which slightly reduces the need for NaOH to control pH, but this slim advantage is completely wiped out by the cost of the much larger anoxic tanks.”

Unlike AMTREAT®, some systems also require an organic source such as methanol or glycol for denitrification. However the large anoxic tanks required to provide the necessary 12 hours’ retention time compared to the much smaller retention time needed in the more effective AMTREAT® system create further cost implications. As Dr Collins points out: “In most applications it is considered beneficial to recycle nitrate as it supplements the oxygen input into the plant’s aeration system.”

The reactor itself is designed as a fully-mixed vessel, in which carefully-controlled conditions ensure the optimum amount of nitrifying bacteria are present in suspended aerobic cultures. Again, the careful choice of sizing of the reactor ensures that even with similar levels of dissolved oxygen to competitor products, the smaller tanks’ energy usage ensures costs are considerably lower.

A proportion of the mixed-liquor suspended solids (MLSS) and return activated sludge (RAS) are recycled to the anoxic tanks. Solids separation is achieved utilising conventional secondary clarifiers. Some competitor technologies do not provide a settlement tank for solids removal, which presents insurmountable challenges in meeting suspended solids limits.

AMTREAT® uses sodium hydroxide for pH control. Competitors utilising CO2 stripping, which uses air and reduces the need for NaOH, are expending valuable air and consequently energy. The AMTREAT® system also provides benefits after a shutdown, as the nitrifying bacteria would enable an initial extra capacity.

Events

May 13 2024 Munich, Germany

May 23 2024 Beijing, China

May 23 2024 Beijing, China

Jun 10 2024 Algiers, Algeria

Jun 10 2024 Frankfurt, Germany