Air Clean Up

Safe Exhaust Management at Council Vehicle and Transport Depots

Oct 21 2013

Councils, public works facilities and general transport depots can make use of a simple, fast and economical way to improve the indoor air quality for employees.

As part of a perpetual drive to maintain good occupational health and safety standards in the workplace, installing an exhaust fan system on the existing roof of any depot allows fast removal of exhaust emissions from vehicles stored there.

Trucks and other vehicles used by the public works depots and transport companies often have a fleet of vehicles parked within a depot overnight before being started in quick succession every working day.

Without installed roof exhaust fans, smoke can fill the depot upon vehicle start-up and employees working in the depot can easily be exposed to this danger.

As an air movement specialist and using it suite of technologies and installation expertise, Fanquip (Australia) map out an optimised solution and place roof fans strategic positions on the depot roof.

By fitting Fanquip Hooded Roof Fans, a site has the advantage of being able to remove entire panels as these units are ‘profiled based’ in equivalent standard sheet lengths to fit quickly and easily into the current roof arrangement.

When instituted, Fanquip roof fans ensure, when drivers start their vehicles, that the internal air is as clear as it possibly can be. All emissions travel upwards to be ventilated and expelled into the atmosphere.

As Fanquip’s Hooded Roof Fans are supplied in any of six standard profile bases (corrugated iron, Trimdek, Super Six, Spandek, Double Rib & Span 4, and Longspan) retrofitting is normally a straightforward procedure.

Using a profile base, installation costs and time were cut by as much as 60%. The units can also be installed by customers quite easily. No upstand or structural supports are needed, while birdmesh protection is provided.

Made from structural fibreglass with metal sleeves and reinforcements, Fanquip Hooded Roof Fans are used in heavy industry applications and

Heat, fumes, odours, smoke and dust can all be alleviated by the use of exhaust ventilating. Fanquip Hooded Roof Fans strategically placed are effective in this workplace environment improvement.

Motor speeds range from 720rpm to 1440rpm, with voltages in either 1Ph 240V or 3Ph 415V.

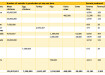

Specifications for each of the roof profiles are as follows:

Corrugated iron profile: Fan diameters available are 400mm, 600mm and 1200mm with a free air volume from 1484 litres/sec to 14000 litres/sec. Motor power ranges from 0.18kW to 2.20kW.

Trimdek: Fan diameters available are 400mm, 600mm, 800mm and 1200mm with a free air volume from 1484 litres/sec to 14000 litres/sec. Motor power ranges from 0.18kW to 2.20kW

Super Six: Fan diameters available are 400mm, 600mm and 800mm and have a free air volume 1484 litres/sec to 6800 litres/sec. Motor power ranges from 0.18kW to 1.10kW.

Spandek: Fan diameters available are 400mm, 600mm and 1200mm. Free air volume ranges from 1484 litres/sec to 4300 litres/sec. Motor power ranges from 0.18kW to 2.20kW.

Double Rib & Span 4: Fan diameters in this profile group are 600mm, and are capable of a free air volume from 3019 litres/sec to 4300 litres/sec. Motor power ranges from 0.37kW to 1.10kW.

Longspan: Fan diameters 600mm and 1200mm, with a free air volume from 3019 litres/sec to 4300 litres/sec. Motor power options are 0.37kW, 1.10W, and 2.20kW.

Events

May 05 2024 Seville, Spain

May 13 2024 Munich, Germany

May 23 2024 Beijing, China

May 23 2024 Beijing, China

Jun 10 2024 Algiers, Algeria