-

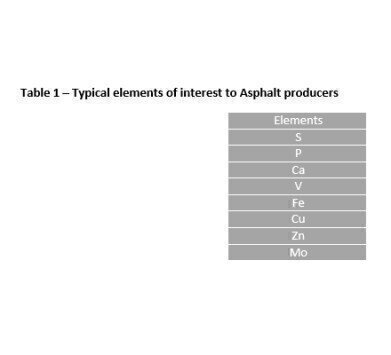

Image 1 – Typical elements of interest to Asphalt producers

Image 1 – Typical elements of interest to Asphalt producers -

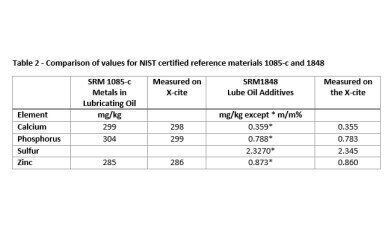

Image 2 - Comparison of values for NIST certified reference materials 1085-c and 1848

Image 2 - Comparison of values for NIST certified reference materials 1085-c and 1848

Measurement and Testing

Quantifying the amount of Metals in Asphalt Binders to comply with environmental regulations

Oct 18 2017

Introduction

The threat to safe drinking water is one of the greatest pollution problems in the world today. Less than 1% of the water on earth is clean and available for potable drinking water. Sources of human drinking water are a mixture of groundwater aquifers and surface water reservoirs. It is important for the safety of these waters that the sources be protected from pollutants. A significant source of pollution to drinking water supplies comes from the discharge of untreated or under treated storm water runoff. More importantly runoff from Asphalt roadways

Background

Bitumen and mineral filler materials in asphalt road surfaces contain different heavy metal species, including Cu, Zn, Cd, and Pb. Roadway runoff can include breakdown products from Asphalt emulsifiers since a significant metal concentration is found in the polar fraction of Asphalt Binders as measured on the Schieff scale. This is of concern to environmental protection agencies like the Federal Highway Administration and the state DOTs, trying to balance road longevity with safety concerns for road construction materials.

Economic factors lead Asphalt makers to look for alternative material sources and to use recycled materials to deal with the waste produced by aging road surfaces and used motor and vegetable oils are natural emulsifiers for recycled asphalt paving and are readily available at low cost.

Elemental composition ranges determined by research

It stands to reason that engine oil additives would also be present in the Asphalt from waste engine oil and one would expect to see concentrations of Zinc, Phosphorus, Calcium and potentially Molybdenum metals in these Asphalt samples as well.

Using XRF to quantify the metal content of asphalt binders

The use of bench top EDXRF to characterise binders before blending them into asphalt cements is possible because the metal values are in the 10s – 1000s of ppms and are readily monitored. The data in generated in this study was collected on a Xenemetrix X-Cite Benchtop using the Analytix software package which has both empirical and fundamental parameter processes for evaluating data.

Table 1 – Typical elements of interest to Asphalt producers (Please refer to image 1)

Validation Results on NIST Standards

Two NIST standards were used to validate the method

Table 2 - Comparison of values for NIST certified reference materials 1085-c and 1848 (Please refer to image 2)

Summary

The monitoring of metals in asphalt additives and ultimately in roadway runoff is able to be monitored using a very simple technique that is both robust and precise, if calibrated correctly, and the interelement effects are correctly assessed and compensated for. Multi element capability as well as very precise excitation conditions characterise EDXRF and make it the ideal instrument for routine laboratory measurements with higher end EDXRF systems having the capability to quantify the carbon content of solid asphalt aggregate compacted into a briquette under substantial hydraulic pressure

Conclusion

EDXRF is a very cost effective method for characterising the metal content in asphalt and asphalt related materials. Relatively simple sample preparation steps and sophisticated matrix correction methods can lead to highly accurate and precise results.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia