Air Monitoring

Finnish ILC for out-stack particulate measurements - recommendations for the practical work based on the observations

Apr 02 2024

Author: Tuula Pellikka and Tuula Kajolinna on behalf of VTT Technical Research Centre

Free to read

Articles are free to download. Unlock the article to be shown more content, graphs and images.

VTT Technical Research Centre of Finland has organized interlaboratory comparisons (ILCs) for stack testing teams in Finland since the 1980s. These measurements have been organized using real stacks. This approach is mentioned also as one of the options for ILCs in European standard EN 17656 “Stationary source emissions. Requirements on proficiency testing schemes for emission measurements”, published in 2022.

Aim of Interlaboratory Comparisons (ILC)?

The aim is to evaluate the performance of (accredited) laboratories, to see if any corrective actions are needed to improve the performance. ILCs between stack testing teams are the most important tool to verify the quality of the emission measurements. Participation in an appropriate ILC is often mandatory to successfully achieve accreditation under ISO/IEC 17025. In Finland, we have always considered dissemination of knowledge to be also one important topic at ILCs. ILCs provide an excellent platform for the exchange of knowledge on new standards and measurement practices. In addition, ILCs can be used to clarify the challenges that teams nowadays face when measuring low emission levels, thus creating important information for the revision work of standards.

ILC in Finland in 2022

Previous ILC for Finnish emission measurement teams was organised during 2022. The measurement place was waste to energy plant, combusting municipal waste in the grid furnace. Measurement platform was located at the height of 20 meters, after the flue gas cleaning units (electrostatic precipitator, textile filter and scrubbers for SO2 and HCl).

During this measurement campaign particulates, gaseous components (O2, CO, CO2, NOx and SO2), velocity and peripheral parameters were measured. Flue gas was saturated and therefore, particulates were measured with out- stack measurement method, according to the principles given in the EN 13284-1. This ILC with out-stack method was organized for the first time in Finland, during previous ILCs in-stack method has been applied.

Out-stack measurement method for particulates is used:

• when flue gas is saturated

• due to technical reasons (in-stack method cannot be applied e.g due to too small measurement ports)

• in some countries (like France, Denmark) out-stack method is the most common method in all particulate measurements

In out-stack measurements, the filter is located outside of the channel, resulting that:

• measurer has to take care of the heating of the filter holder and the probe

• probe, its nozzle and inlet part of the filter holder shall be rinsed (water-acetone) after the measurements.

Deposits found in rinsing solution are part of the particulate mass, meaning that the particulate concentration is sum of the deposits found in the rinsing solution and of the mass on the filter.

Out-stack method requires more operations to be performed at the field circumstances compared to in-stack-method (where there is no need for rinsing).

Seven emission measurement teams took part to this ILC and six teams to particulate ILC (teams A, C, D, E, F and G). All teams had accreditation according to EN ISO/IEC 17025 for the components that they measured.

This article focuses on particulate measurements and their observations.

Results and observations from particulate results and field performance during ILC in 2022

Figure 1 and 2 show particulate results measured by stack testing teams A, C, D, E, F and G.

Team A had high particulate concentrations in all their three samples, the reason for it was not found out.

For stack testing teams C, F and G, nearly all particulate results were below limit of quantification (LOQ), 1-2 mg/m3(n). Team G had higher concentrations compared to teams C and F. The most probable reason for this was the different balance between pre- and post- weighing’s (due to maintenance of the balance). In addition, the resolution of this balance was not sufficient for these low concentrations.

In EN 13284-1 it is mentioned that typically dust deposits upstream of the filter are typically 10-30 % of the total dust. However, during this ILC these deposits were clearly larger. Note! In the EN 13284-1 it is mentioned that the upstream parts will be rinsed after each measurement series. However, during this ILC teams were asked to perform the rinsing after each sample.

Figure 3 shows particulate distribution between the filter and rinsing solution. Possible reasons for this are for example contamination which could easily happen while probe parts are rinsed at the field and characteristics of the dust.

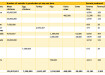

Table 1 shows measurement uncertainties (MU) reported by stack testing teams.

Table 1. Measurement uncertainties for particulates, Finnish ILC in 2022 for teams A, C, D, E, F and G

As we can see from the Table 1, measurement uncertainties vary remarkably.

During this ILC, also the practical working procedures during measurements were evaluated.

Table 2 shows the results of field audit for particulate measurements.

Table 2. Observations from the field audit for particulate measurements

Common challenge for many teams in rinsing procedure was that the front part of the filter was not rinsed, as it should be according to EN 13284-1. Some teams did not rotate or tilt the probe in order to have efficient rinsing. All teams, except one (team D) used proper rinsing solutions (acetone and water).

Mistakes with the field blank procedures were for example:

o field blank was considered to be such a filter that is only taken to the field (it was not inserted to the filter holder at all)

o the probe was inserted to the stack (though it is not supposed to be inserted)

Conclusions

Following recommendations for the improvement of particulate measurement procedures were given to Finnish stack testing teams based on this ILC:

- chemical blank for rinsing solution should be studied. This value can be subtracted from the deposits

- suitable material should be chosen for the containers where the rinsing solutions are evaporated (plastic is not recommended)

- attention should be paid to the weighing procedure:

o resolution of the balance shall be 0,01 mg (not 0,1 mg which is still allowed to be used according to EN 13284-1)

o attention shall be paid to electrostatic charges, ambient temperature and pressure

o while weighing the filters, take your time, do not rush!

- importance of reference parts is emphasized. These are not only for filters but also for large volume parts (like beakers). Based on this information, weighing corrections can be applied to the results

- guidance is still needed for the calculation of measurement uncertainties.

Some teams followed the instructions given in the standards carefully while others had some challenges in this respect. This shows how important it is to take care of the continuous training of the personnel and that the competence of the personnel is also monitored frequently. ILCs are a perfect tool for this!

All results, with the conclusions, are given in the final report (in Finnish, Pellikka et al, 2023).

References

Comité Européen de Normalisation. 2022. Stationary source emissions. Requirements on proficiency testing schemes for emission measurements. EN 17656. https://www.cen.eu/

Comité Européen de Normalisation. 2017. Stationary source emissions. Determination of low range mass concentration of dust. Part 1: Manual gravimetric method. EN 13284-1. https://www.cen.eu/

Pellikka, T. & Kajolinna, T. (2023). Kansalliset päästöjen vertailumittaukset 2022: VERMI-projektin yhteenveto. VTT Technical Research Centre of Finland. VTT Technology, No. 417. https://doi.org/10.32040/2242-122X.2023.T417

Free to read

Articles are free to download. Please login to read this article or create an account.

Events

May 05 2024 Seville, Spain

May 13 2024 Munich, Germany

May 23 2024 Beijing, China

May 23 2024 Beijing, China

Jun 10 2024 Algiers, Algeria